From 1686e4a68a8ed79f48615ff64fa1f33d939be149 Mon Sep 17 00:00:00 2001

From: Mohammed Omer <momer93@hotmail.com>

Date: Sat, 13 Mar 2021 22:17:30 +0100

Subject: [PATCH] m

---

docs/machines/Desktop3DPrinter.md | 41 ++++++++++++++++++++++++++++++-

docs/machines/Plasma Cutter.md | 3 +++

2 files changed, 43 insertions(+), 1 deletion(-)

create mode 100644 docs/machines/Plasma Cutter.md

diff --git a/docs/machines/Desktop3DPrinter.md b/docs/machines/Desktop3DPrinter.md

index 3ef7352..26f8e65 100644

--- a/docs/machines/Desktop3DPrinter.md

+++ b/docs/machines/Desktop3DPrinter.md

@@ -1,6 +1,6 @@

# Desktop 3D Printer

-Preliminary research was carried out to see which open source designs and commercial 3D are popular in the 3D printer community. These will be used as a starting point for the development.

+Preliminary research was carried out to see which open source designs and commercial 3D are popular in the 3D printer community. These will be used as a starting point for the development of the desktop 3D Printer.

Various repositories such as Youtube, Github, Instructables, GrabCad, Thingiverse, Personal Blogs and Technical Forums were searched.

@@ -74,6 +74,8 @@ Various repositories such as Youtube, Github, Instructables, GrabCad, Thingivers

---

+There are many cheap 3D printer kits that are available these days like the Creality or Tronxy models. These work and do the job but the parts are not optimum or quality components. More often than not users upgrade their cheap printers and end up spending twice as much in the end by replacing components. It is preferrable then to build your own printer from scratch where you get to decide what components you would like to have in the printer. Also if something breaks, you know exactly what to do or how to fix it.

+

## Choosing a 3D Printer for the OLSK

The aim of the Open Lab 3D printer is to develop a DIY 3D Printer design that is robust and reliable. It should be possible for anyone to build it, with the posssibility of modifying it according to their budget, requirements and available resources.

@@ -176,6 +178,9 @@ Part of the design criteria is to fit the power supply and electronics under the

- BL touch

- IR sensor

- Piezo Sensor

+

+[Autolevelling sensors review](https://www.youtube.com/watch?v=il9bNWn66BY&t=8s)

+

5. Rasberry Pi for Octoprint (WiFi printing)

6. Fans for cooling electronics

- 6020 Fans for electronics enclosure cooling

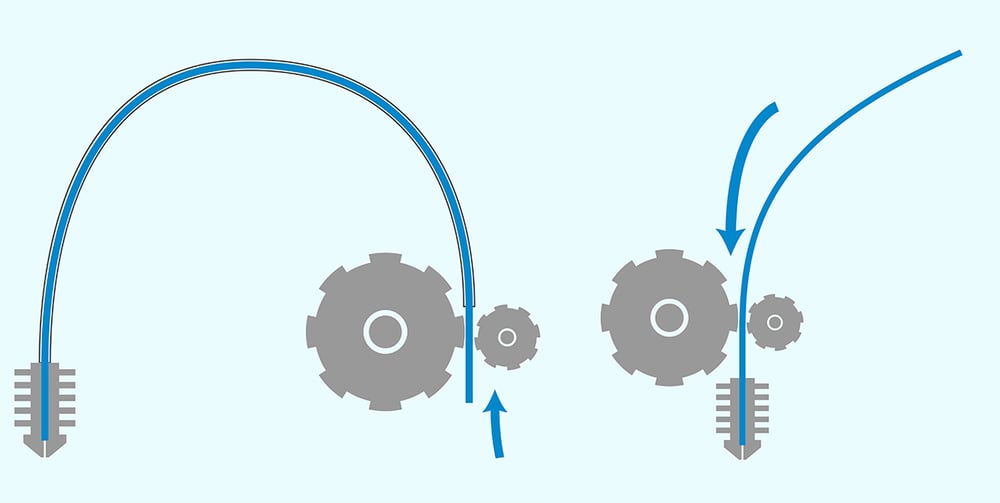

@@ -196,6 +201,8 @@ Most filament 3D printers use either direct or bowden extrusion. Both set-ups us

+[Direct Drive Extruder Selection Guide](https://3dprintbeginner.com/direct-drive-extruder-buyers-guide/)

+

## **Z-axis design for lifting Build Platform**

@@ -274,6 +281,7 @@ Ensure that it is not possible for the user to touch the SSR terminals or any ot

If the bed is moving, use highly-flexible wire or cable with a sufficient voltage rating to connect the moving bed heater to the stationary wiring. Cable intended for use in multimeter tests leads is one possibility.

If the bed is moving, you must use strain relief at both ends of that cable, to reduce the risk of the cable fracturing with repeated movement.

If the bed is moving, use a cable chain or similar to make sure that the cable can't get chafed or trapped.

+

Provide a fuse for the bed heater circuit or the whole printer appropriate to the current draw and the current rating of the mains lead. One option is to use a panel mount IEC mains inlet connector with a switch, neon indicator and fuse built in. See http://www.thingiverse.com/thing:965396 for an example setup on a delta printer.

It is highly recommended that you power the printer via a Ground Fault Current Interruptor (GFCI) - more commonly called a RCD (Residual Current Device) in the UK - to protect against electric shock in the event of a fault.

If in doubt, consult a qualified electrician.

@@ -281,6 +289,7 @@ If in doubt, consult a qualified electrician.

Low voltage (12V or 24V) DC bed heater

Use a low voltage drop DC/DC SSR such as the Auber Instruments MGR-1DD80D100 or Crydom DC100D40. The SSR may need a heatsink, depending on the current. Do not be tempted to use a cheap DC-DC SSR such as the SSR-40DD, which is basically useless for this application because of its high voltage drop.

+ If your heater will reach dangerously high temperatures if it is left on at full power, you should always use a TCO to guard against electronics or firmware failure. The alternative is to choose the heater power carefully so that it is powerful enough to reach the temperatures you want quickly, but not so powerful as to reach a dangerously high temperature when left fully on for a long time.

### Choosing Power Supply

@@ -322,6 +331,33 @@ If you accidentally touch both AC terminals, or if they short to each other, it

https://all3dp.com/2/3d-printer-power-supply-how-to-choose-the-right-one/

+### 3D printer Wiring

+

+One of the most important things about your 3D Printer is the Wiring. If the gauge is too small you won’t get enough current to your parts and can even have a disaster on your hands. Too large of a gauge and you might have a problem fitting those crimped terminals into the connectors.

+

+So, the first thing to look for in a wire type is a stranded wire.

+

+The reason being your printer will create thousands of cycled movements and if your wire is a solid it will be susceptible to break over the duration of repeated abuse. The stranded wire allows for the cable to flex and move without breaking over time.

+

+The RepRap Wiki page recommends using 22AWG or 20AWG

+

+#### **3D Printer Wiring Connectors**

+

+**Dupont Connectors**

+

+These connectors work great for RAMPS and Rumba type controller boards with open Pin Headers.

+

+

+

+The JST connectors are what are used on the 32 bi boards such as the MKS, AZteeg etc.

+

+

+

+[Source](https://3daddict.com/3d-printer-wiring/)

+

+

+Wiring exmaple of the MKS Sbase V1.3 Board -

+

**Inserting threaded inserts in Printed Parts**

@@ -352,3 +388,6 @@ https://all3dp.com/2/3d-printer-power-supply-how-to-choose-the-right-one/

[Thingiverse Post](https://reprap.org/forum/read.php?397,530210) of finetuning the CoreXY setup

[Instructable on good practices for building 3d printer](https://www.instructables.com/An-Almost-Reliable-High-Precision-3D-Printer-Son-o/)

+

+

+A nice way of presenting bill of materials

\ No newline at end of file

diff --git a/docs/machines/Plasma Cutter.md b/docs/machines/Plasma Cutter.md

new file mode 100644

index 0000000..d0dc293

--- /dev/null

+++ b/docs/machines/Plasma Cutter.md

@@ -0,0 +1,3 @@

+# Open Source Plasma Cutter Designs

+

+1. [Office Plasma Cutter](https://www.thingiverse.com/thing:3645035) from thingyverse user DerM4209

--

GitLab