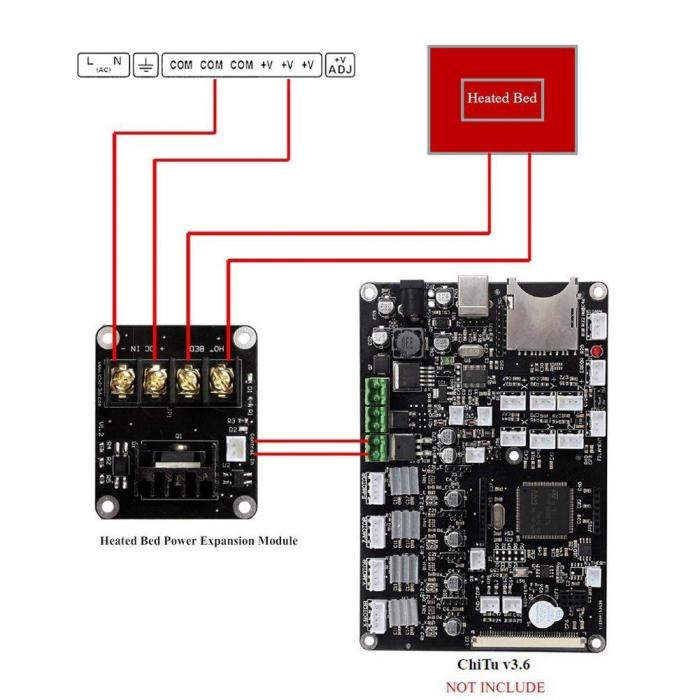

diff --git a/docs/machines/Desktop3DPrinter.md b/docs/machines/Desktop3DPrinter.md index 54eab2978ad351c0d4a3f79725f266953dbddfe5..3ef73521dc5ad73d6641df58fdccd4560cd33918 100644 --- a/docs/machines/Desktop3DPrinter.md +++ b/docs/machines/Desktop3DPrinter.md @@ -259,12 +259,69 @@ Minimum heatbed power to heat the aluminium build plate to print PLA (70degC) is - use 12AWG wire from PSU>Mosfet and 12AWG Silicon high temp wire from mosfet to heater +Bed heater driven using a Solid State Relay +You can use a solid state relay (SSR) to switch the bed heater by connecting its control terminals to the Duet bed heater terminals. Make sure that you get the wires to the + and - control terminals of the SSR the right way round. + +Caution: when using a high-powered bed heater, in the event that temperature control fails and the bed heater is turned on at full power for an extended period of time, you should either make sure that the bed heater and bed will not exceed a safe temperature, or else install a thermal cutout to disconnect the bed heater or its power supply before excessive temperatures are reached. + +Mains voltage AC bed heater +Use a zero-crossing DC-AC SSR such as Crydom D2425, Kudom KSI240D25-L or Fotek SSR-25DA (note: many Fotek SSRs on sale are fakes, using triacs rated at lower current than the marked rating of the SSR). For 230V bed heaters, SSR-10DA may be sufficient. If your bed heater draws more than about 1/4 of its rated current then the SSR may need a heatsink. + +Take appropriate safety precautions when using a mains voltage bed heater. In particular: + +Connect metal parts of the printer to mains ground. This includes the printer frame, the bed plate if it is conductive (e.g. aluminium), and any other metal parts that the bed heater or SSR wiring might come into contact with if wires break. +Ensure that it is not possible for the user to touch the SSR terminals or any other exposed mains wiring, or for you to touch the mains wiring when you are working on the printer with power applied. If your SSR is not supplied with a clear plastic safety cover, buy one (for the Crydom SSR listed above, the part number is KS101). +If the bed is moving, use highly-flexible wire or cable with a sufficient voltage rating to connect the moving bed heater to the stationary wiring. Cable intended for use in multimeter tests leads is one possibility. +If the bed is moving, you must use strain relief at both ends of that cable, to reduce the risk of the cable fracturing with repeated movement. +If the bed is moving, use a cable chain or similar to make sure that the cable can't get chafed or trapped. +Provide a fuse for the bed heater circuit or the whole printer appropriate to the current draw and the current rating of the mains lead. One option is to use a panel mount IEC mains inlet connector with a switch, neon indicator and fuse built in. See http://www.thingiverse.com/thing:965396 for an example setup on a delta printer. +It is highly recommended that you power the printer via a Ground Fault Current Interruptor (GFCI) - more commonly called a RCD (Residual Current Device) in the UK - to protect against electric shock in the event of a fault. +If in doubt, consult a qualified electrician. + +Low voltage (12V or 24V) DC bed heater +Use a low voltage drop DC/DC SSR such as the Auber Instruments MGR-1DD80D100 or Crydom DC100D40. The SSR may need a heatsink, depending on the current. Do not be tempted to use a cheap DC-DC SSR such as the SSR-40DD, which is basically useless for this application because of its high voltage drop. + + ### Choosing Power Supply [Info](http://customize-3d.com/how-to-calculate-power-requirements-of-3d-printer-safeguard-controller.html) Connected Heated bed with Mosfet and power supply  +The next most important rating for your 3D printer power supply is output current. As previously stated, this will be the limiting factor for your heated bed and the total number of hot ends you are operating. + +The easiest way to calculate how many amps you need is to look at the wattage of the supply, and the rating of your heated bed. Generally, your control board, one hot end, five motors, and a few other electronics (sensors and fans) can be said to use about 100 watts of power. Add in what your heated bed is rated for, and you’ll have a minimum required wattage for your power supply. + +To get the amperage, simply divide by the output voltage, e.g. 360W / 12V = 30A. + +Here are some examples: + +- The standard minimum for 3D printers is usually 240 watts (12 volts @ 20 amps). That would be enough for a printer with a single hot end and a heated bed around 180 x 180 mm. +- With a 200 x 200 mm bed or a second hot end, you’d be better off with 300 watts (12V @ 25A). +With both a second hot end and a 200 x 200 mm heated bed, or single extruder with up to a 300 x 300 mm heated bed, 360 watts are standard (12V @ 30A). +- With anything larger than that, a power supply rated upwards of 400W would be recommended. +With a 24V PSU, the rules change slightly, as you don’t need quite as much current. Still, we would recommend sticking to the above standard for the best possible operation. + +There are two main kinds of power supplies: + +ATX PSUs are generally meant for PCs, and while they are manufactured to a higher standard than LED supplies, they require modification to be used with 3D printers. They are also usually more expensive, especially at higher ratings, but incorporate many more safety features, not least of which is closed AC wiring and (usually) a power switch. + +LED PSUs are what you will usually find on a kit like the Anet A8 — that clunky silver box with the really dangerous wiring terminal. These supplies are generally pretty reliable, and they’re cheap and easy to wire. However, there’s no real standard for these supplies to be manufactured to. That means quality will vary a lot based on the seller and manufacturer. The single biggest issue with these supplies is the open AC screw terminals, which are a safety hazard if left uncovered. + +The best way to check an LED PSU is with a voltmeter or multimeter. First, wire up your supply to the appropriate power cord, making sure that it is not plugged in while you are handling the wires. When done, plug in your supply, and check the voltage across the output terminals. Be very careful not to touch or short the input AC power terminals. + +When checked with a voltmeter, the output should be nearly the same as the indicated output voltage. You may need to fiddle with the small potentiometer next to the screw terminals, as this will change the output regulation slightly. Having the voltage slightly higher will help with an underpowered heated bed, but be careful not to overpower your other components. + +Once you know your supply works, wiring it into your printer should be relatively easy. This is especially true with screw terminals and the plug-and-play style setup adopted by most manufacturers. Again, be very sure that you never do any wiring while the supply or the printer is plugged in. Also, be very careful to not touch or short the AC terminals of your PSU while running tests. + + + + +If you accidentally touch both AC terminals, or if they short to each other, it’s very easy to electrocute yourself or burn things down. Therefore, to finish up we would recommend you avoid either of these instances by investing the time and filament printing a covering for any exposed wires and terminals. It’s also a good idea to add a switch and a fuse in the process. Example of covering the PSU terminals below. + + +https://all3dp.com/2/3d-printer-power-supply-how-to-choose-the-right-one/ + **Inserting threaded inserts in Printed Parts**  diff --git a/docs/machines/Pick & Place Machine b/docs/machines/Pick & Place Machine.md similarity index 100% rename from docs/machines/Pick & Place Machine rename to docs/machines/Pick & Place Machine.md diff --git a/docs/machines/SLS Printer b/docs/machines/SLS Printer.md similarity index 100% rename from docs/machines/SLS Printer rename to docs/machines/SLS Printer.md diff --git a/docs/software/CNC Control Software b/docs/software/CNC Control Software deleted file mode 100644 index b9aa5e8380eae479d3c796478ea3a7dace795736..0000000000000000000000000000000000000000 --- a/docs/software/CNC Control Software +++ /dev/null @@ -1,2 +0,0 @@ -There are many different software solutions out there. Some are free or open source, while others are linked to a specific control board. -